A 3-wire alternator is a reliable and efficient charging system used in a lot of cars, offering better voltage regulation and performance compared to single-wire setups. However, if you plan on wiring one correctly – ensuring proper battery charging and preventing electrical issues – you’re going to need a 3-wire alternator wiring diagram.

So, to help you out, in this guide, we’ll be walking you through the wiring process step-by-step. Along the way, we’ll explain the function of each wire, as well as provide a very clear 3-wire alternator wiring diagram to help simplify the installation. Whether you’re upgrading your old alternator or if you’re replacing an old unit, here’s a quick TL;DR:

| Wire | Connection | Function |

|---|---|---|

| Battery Wire (B+) | Connects to the battery or starter solenoid | Delivers main power output |

| Sense Wire (S Terminal) | Connects to the battery or power distribution point | Monitors system voltage for better regulation |

| Exciter Wire (L Terminal) | Connects to the ignition switch through a warning light | Activates the alternator to start charging |

Now, let’s dive into the step-by-step wiring process:

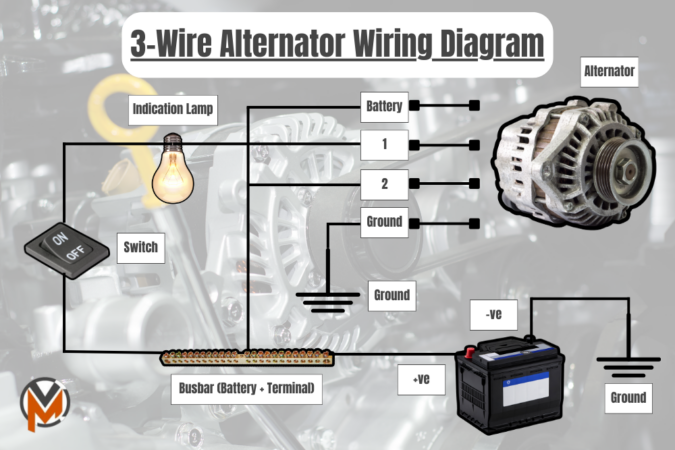

3-Wire Alternator Wiring Diagram

If you’re working on an alternator or your car’s charging system, a 3-wire alternator wiring diagram is handy to have around. With that in mind, here’s what it looks like:

A three-wire alternator wiring diagram shows how the various components of a circuit are connected. The circuit is made up of three major wires: a positive cable for the battery, a voltage-detecting wire, and an ignition wire. The engine is connected to the ignition input wire. The voltage-detecting cable detects the voltage and connects to the rectifier.

Meanwhile, the power wire delivers power that’s been generated by being driven by the engine via the drive belt. Multi-purpose alternators with built-in voltage rectifiers for power sensing are available. Unlike single-wire alternators, they may generate and rectify electricity in the same circuit. It helps to guarantee that all components receive controlled voltage.

A 3-wire alternator wiring diagram has three wires: the primary charge wire, a third wire that can jump between the regulator and the battery stud, and the exciter wire. The 3-wire alternator wiring diagram is not as complex as it seems, as only two additional wires are integrated into the rest of the electrical system and the alternator.

What Is A 3-Wire Alternator?

The 3-wire alternator wiring diagram shows three electrical connections, as its name suggests. The large connector that connects to the battery is the first. The primary current flow charges the battery and drives the car when the engine is running. There are two smaller terminals on the top of the alternator, typically spade terminals. The sense terminal is one of them.

You must connect the alternator’s output to this terminal for it to sense and adjust the output voltage. The exciter is the opposite terminal. This is what energizes the alternator’s field. An alternator is a device that converts mechanical energy into electrical energy, and it’s especially useful in cars. And, a proper diagram is nice to have if you’re working with one.

Ultimately, this allows your alternator to continually generate electricity, recharge your car’s battery, and serve as a power source. It does so by converting mechanical energy to electrical by switching from alternating current to direct current. Parts used for energy generation are the rotor and stator, as the rectifier aids in converting AC to DC.

What Are The Parts Of An Alternator?

Before you dive into a 3-wire alternator wiring diagram, it’s handy to know what each of the alternator’s parts does. Here are some of the noteworthy components inside an alternator:

- Rotor – When your car’s engine is running, a drive belt pulley system spins the rotor, generating a rotating magnetic field within the alternator.

- Stator – As the alternator’s rotor spins, the changing magnetic field induces a voltage across the stator windings, generating alternating current (AC).

- Rectifier – The rectifier allows current flow in only one direction. By rectifying the AC voltage, the rectifier ensures a steady and consistent flow of DC power.

- Voltage Regulator – Regulates the voltage and current supplied to prevent overcharging the battery and ensure a stable power supply to your car’s electrical system.

- Brushes & Slip Rings – These components enable the flow of current to energize the rotor and create the magnetic field required for power generation.

- Drive Belt & Pulley – As your car’s engine rotates the drive belt, it spins the pulley on the rotor shaft, setting the alternator in motion.

- Bearings – These bearings, including the slip ring end bearing and the drive end bearing, minimize friction and ensure smooth operation of the alternator.

- Housing – The alternator’s housing encloses and protects its internal components, and is designed to dissipate heat effectively.

Understanding A 3-Wire Alternator Wiring Diagram

The alternator contains a complicated network of wires to make it all work reliably. The exciter wire, as well as positive and negative wires, are the principal wirings. The exciter wire is used to turn on the voltage regulator and is linked to the L terminal of an alternator. An exciter wire is necessary to create the voltage required to start the alternator.

Then, the positive and negative cables are small and connect to the battery’s positive and negative terminals. The alternator is also connected by the battery charging cable. It solely charges the battery and doesn’t provide power to any other devices. Meanwhile, the ignition input wire (to the key switch) activates the voltage regulator.

Aside from that, the stator and rotor are two elements of a three-wire alternator wiring diagram. The three-phase armature winding is found in the stator, while the field winding is found in the rotor. Batteries can only store DC power. Therefore, the alternator includes a rectifier circuit that converts three-phase AC power to DC power.

The field winding is connected to a voltage regulator circuit through the slip ring. The voltage regulator circuit receives the DC power from the output of the rectifier circuit and distributes it to the field winding. If the output voltage and current exceed their normal levels, the voltage regulator will decrease the power supplied to the field winding.

How Do You Wire An Alternator?

As complex as your car’s alternator might be, wiring it together isn’t as difficult as it may appear. You could easily do it in your garage. All you need are simple tools such as a wrench, wire crimper, and multimeter.

Whether you’re repairing or rebuilding one, or if you’re upgrading an old alternator, it’s not that hard to do. Particularly, if you have a 3-wire alternator wiring diagram to help you. Here’s a rough idea of what to do:

Step 1 – Unplug The Negative Terminal Of Your Car’s Battery

Remove the negative terminal from the vehicle battery before starting anything. This is not a difficult chore to complete. However, anything involving electricity or the vehicle battery should be approached with caution. Therefore, while not an integral step to get things done, it’s a major step to consider for your safety.

Step 2 – Assemble The Alternator Mounting Brackets

The second phase here could be the most difficult. But don’t worry, here are some easy steps on how to proceed. It’s also worth noting that you might be able to find brackets in a junkyard that will work with minimal changes, which will save you money. Or, you can make your own brackets out of 14-inch flat stock steel that’s about 1 inch wide if you can’t find done.

The brackets would then be mounted using the generator bracket’s original mounting holes in the engine block. It is critical to ensure that the pulleys are properly aligned with the drive belt and that the bracket allows for drive belt adjustment. After that, the alternator and new drive belt can be attached, as per usual. Now, continue to the next step.

Step 3 – Connect the Positive Terminal Of The Battery To The Output Bolt

By now, you’ve already completed the most difficult portion. Now, connect the output bolt on the back of the alternator to the positive terminal of the battery with 10-gauge wire and solderless ring terminals. This can also be made on the starter solenoid, which is where the positive cable is. Then, connect the battery’s positive terminal to the starter solenoid.

Step 4 – Plug-In The Negative Battery Cable

Connecting the battery negative cable is the final step. There are many options on the market, but for now, we’ll be using AC Delco 3 as an example. Their 3 wire alternator has a high output, a compact construction, and is simple to operate. The required brackets can be used to convert this alternator to work with any other vehicle in just a few simple steps.

Step 5 – Unplug The Battery’s Negative Terminal

Okay, for now, we’ve already sorted out the old alternator. Now, it’s time to wire in a new 3-wire alternator. The first step in wiring a 3-wire alternator to your vintage vehicle is to disconnect the battery negative terminal, as I explained in the preceding step-by-step guide. This is a crucial safety and precautionary step that should not be skipped.

Step 6 – Connect The Wire To The Output Stud

The next step is to use a solderless ring connector to connect a piece of 10-gauge wire to the output stud on the rear of the alternator. The starter solenoid should be linked to the other end of this wire. Connecting it to the same terminal as the positive battery line requires simply a few straightforward steps.

Step 7 – Connect The Alternator Connector To The Receptacle Of The Alternator

The next step is to connect the new alternator connector to the receptacle on the old alternator. It’s not difficult to solder a 14-gauge wire to the smaller pigtail from the connector. This wire connects to the IGN terminal on the ignition switch. Finally, connect a small 12-volt caution light in series with this cable.

Step 8 – Splice A 10-gauge Wire To The Bigger Wire On The Alternator Plug

Next, splice a 10-gauge wire to the bigger wire on the alternator plug. Connect the wires with a solderless connector to complete the procedure. Make sure the wire is long enough to connect to the same starter solenoid terminal as the positive battery cable and the alternator output wire. Finally, use a solderless ring connection to attach the wire to the terminal.

Step 9 – Putting In The Final Touches

Last but not least, it’s time to connect the battery negative terminal to the AC Delco 3-wire alternator. After you’ve finished wiring, you’ll be able to utilize it and operate it with ease. Your car will now run more efficiently by replacing the old generator with a 3-wire alternator. As easy as that was, a 3-wire alternator wiring diagram definitely makes this easier.

3-Wire Alternator Wiring Diagram Common Mistakes & Troubleshooting

From what we’ve discussed thus far in these diagrams, wiring a 3-wire alternator into your car might seem straightforward. However, even the smallest of mistakes can lead to charging issues, warning lights, or even damage to your electrical system. So, here are some common wiring errors, symptoms to watch for, and troubleshooting steps to fix them:

1 – Incorrect Battery Wire (B+) Connection

- Mistake: Accidentally connecting the battery wire to the wrong terminal or not securing it properly.

- Symptoms: You might notice that the alternator doesn’t charge the battery, or if your car runs only until the battery drains.

- Fix: You need to ensure that the B+ terminal connects directly to the battery-positive post. Or, make sure that the starter solenoid with a proper fuse in line.

2 – Sense Wire (S Terminal) Not Connected Properly

- Mistake: You accidentally left the sense wire unconnected, or you accidentally attached it too far from the battery.

- Symptoms: You’ll notice overcharging or undercharging, due to incorrect voltage sensing.

- Fix: To solve this, you can connect the sense wire as close to the battery as possible (e.g., at the fuse box or main power distribution point) to get an accurate voltage reading.

3 – Exciter Wire (L Terminal) Issues

- Mistake: You forgot to use a warning light or resistor when connecting the exciter wire.

- Symptoms: You’ll see that the alternator doesn’t start charging, or your battery warning light doesn’t turn on/off properly.

- Fix: To fix this, you’ll have to use a 12V indicator light or a 35-500 ohm resistor in-line between the ignition switch and L terminal to regulate current flow.

4 – Poor Grounding

- Mistake: Your alternator housing isn’t properly grounded to your car’s engine or chassis.

- Symptoms: Signs of failure include intermittent charging, dim headlights, or electrical system fluctuations.

- Fix: You’ll need to ensure that the alternator mounts to a clean, unpainted metal surface. You could also add an extra ground wire from the alternator case to the chassis if necessary.

5 – Using Too Thin or Old Wiring

- Mistake: Using undersized wires that can’t handle the alternator’s current output is a common mistake.

- Symptoms: Overheating wires, melted insulation, or poor charging performance might occur.

- Fix: You have to use at least 8-gauge wire for the battery wire, and a 10-12 gauge wire for the sense and exciter wires.

6 – Ignoring Pulley and Belt Condition

- Mistake: You mistakenly use a loose or worn alternator belt, which reduces efficiency and causes undercharging.

- Symptoms: Some signs you might notice include the battery light flickering, squealing noise, or fluctuating voltage.

- Fix: You can easily fix this by adjusting the belt tension and replacing it if worn or glazed.

7 – Testing Your Wiring Before Finishing Up

Now, once you’ve made any of these troubleshooting steps, before starting your engine, make sure that you always:

- Use a multimeter to check your alternator connections and confirm that it’s getting the proper voltage.

- Ensure that your alternator produces between 13.5V to 14.8V at the battery when it’s running.

- It’s a good idea to listen out for unusual noises and check for warning lights on the dashboard.

3-Wire Alternator Wiring Diagram – 1-Wire vs 2-Wire vs 3-Wire Alternators

If you’re still unsure about whether or not you should use a 1-wire, 2-wire, or 3-wire alternator, maybe this handy little table we’ve prepared might help:

| Feature | 1-Wire Alternator | 2-Wire Alternator | 3-Wire Alternator |

|---|---|---|---|

| Wiring Complexity | Simplest setup—only needs a battery wire. | Moderate—adds an exciter wire for better control. | Most complex—includes battery, sense, and exciter wires. |

| Voltage Regulation | Self-regulates, but it lacks precision. | More precise than 1-wire, but it relies on the exciter source. | Most accurate—uses remote voltage sensing to adjust output. |

| Charging Efficiency | It could suffer voltage drop over distance. | More stable than 1-wire, but not as refined as 3-wire. | Delivers the best performance by adjusting voltage based on actual battery needs. |

| Startup Activation | Requires higher RPM to begin charging. | Starts charging as soon as the engine runs. | Begins charging instantly when the ignition turns on. |

| Battery Voltage Sensing | Reads the voltage at the alternator, not at the battery. | Has no dedicated sensing wire. | Uses a sense wire to monitor and adjust voltage directly at the battery. |

| Use Case | Works well in simple setups like classic cars and hot rods. | Fits basic electrical upgrades and moderate power needs. | Handles high-demand electrical systems in modern vehicles. |

| Best For | Cars with minimal electrical accessories. | Vehicles with basic upgrades that need better voltage stability. | Daily drivers, EFI-equipped vehicles, and systems with electric fans or sound systems. |

I cannot get alternator to charge–dum light will only light if grounded–1157 from tail light,perhaps this light is too big?New alternator 40amp made to fit l3e Mitsubitshe(diesel)Will a small LED type light work as a dummy?Please help thank you

It seems like you’re having trouble getting your alternator to charge, and you’ve mentioned that the dummy light only lights up when grounded. It’s possible that the 1157 bulb from the tail light might be too big for the dummy light function.

Using a small LED type light as a replacement for the dummy light could be worth trying. LED lights generally have lower power requirements and might be more suitable for this purpose. However, it’s important to ensure that the LED light you choose matches the specifications and requirements of your alternator and vehicle.

If you decide to go ahead with the LED light, make sure it can handle the voltage and current output of your alternator. Additionally, check if any modifications or adjustments need to be made to the wiring diagram to accommodate the use of an LED light.

It’s also worth considering other potential issues that could be causing the alternator not to charge. Double-check all connections and wiring to ensure they are secure and correctly installed. If you’re still experiencing difficulties, consulting a professional or an experienced mechanic might be beneficial in troubleshooting the problem more effectively.

I hope this helps, and good luck with resolving the issue with your alternator!

hi ,i have a bosch alternator with three screw on connections but only two wires the red feed and another thinner one,i took it off car and now cant remember where the thin one goes to, of the two smaller connections one has a positive symbol the other has nothing , where do i put small wire from somewhere around engine

Hi Charles,

In a typical Bosch alternator with three screw-on connections, here’s how they are usually configured:

1. B+ Terminal (Positive Symbol): This is the main power terminal and is typically connected to the battery or the positive side of the electrical system. It should have a thick wire (usually red) attached to it, which goes directly to the positive terminal of the battery. This terminal provides power to the alternator to charge the battery and power the vehicle’s electrical systems.

2. D+ or W Terminal: The second small terminal with no symbol (blank) or marked “D+” or “W” is typically the exciter terminal. It is used to provide the initial voltage to activate the alternator when the ignition is turned on. This terminal should be connected to the ignition switch, typically through a warning light or indicator on the dashboard. When you turn on the ignition, this terminal receives voltage, and the alternator starts generating power.

3. DF Terminal (Optional): In some Bosch alternators, there might be a third terminal labeled “DF.” This terminal is used for various purposes, such as controlling the alternator’s output voltage. It may not always be present in every alternator, and its function can vary depending on the specific alternator model.

Based on your description, it sounds like the thinner wire you have may be the exciter wire (D+ or W terminal). This wire should typically be connected to the ignition switch or a warning light in the dashboard. It’s essential to consult the wiring diagram for your specific vehicle or the alternator model to ensure the correct connection.

If you’re unsure about the wiring or don’t have access to a wiring diagram, I recommend seeking assistance from a qualified mechanic or an automotive electrical specialist who can help you properly connect the wires to avoid any electrical issues. Incorrect wiring can lead to alternator or electrical system problems in your vehicle.

i have three terminals on my alternator and only two wire which one do i leave