Anyone with a basic idea about the working of an internal combustion engine must be familiar with the crankshaft and camshaft. The working of these important components of the engine is paramount for its smooth operation. This is where the camshaft position sensor jumps into the scene.

The camshaft position sensor does an important job in keeping the engine running in its top nick. But what happens when it fails? How do you know that it has failed? How much will it cost you to replace the camshaft position sensor? These questions looming in your mind will be answered in this story. Keep reading.

What Is A Camshaft Position Sensor?

Before we jump into the working of a camshaft position sensor, you should understand the working of a camshaft. Maybe throw in an explanation of where the crankshaft fit in as well. This can help you paint the whole picture in your mind.

Functions Of The Camshaft

The camshaft is responsible for the opening and closing of the valve. Specially designed lobes on the camshaft control the valve opening and closing. The rotation of the camshaft takes power from the crankshaft via a timing chain or belt. Read more about timing chains or belts here.

The crankshaft in turn gets its rotation from the pistons moving up and down. As the crankshaft rotates, the camshaft rotates with it. The lobes on the camshaft push against the spring-loaded valves above each cylinder opening or closing them as needed.

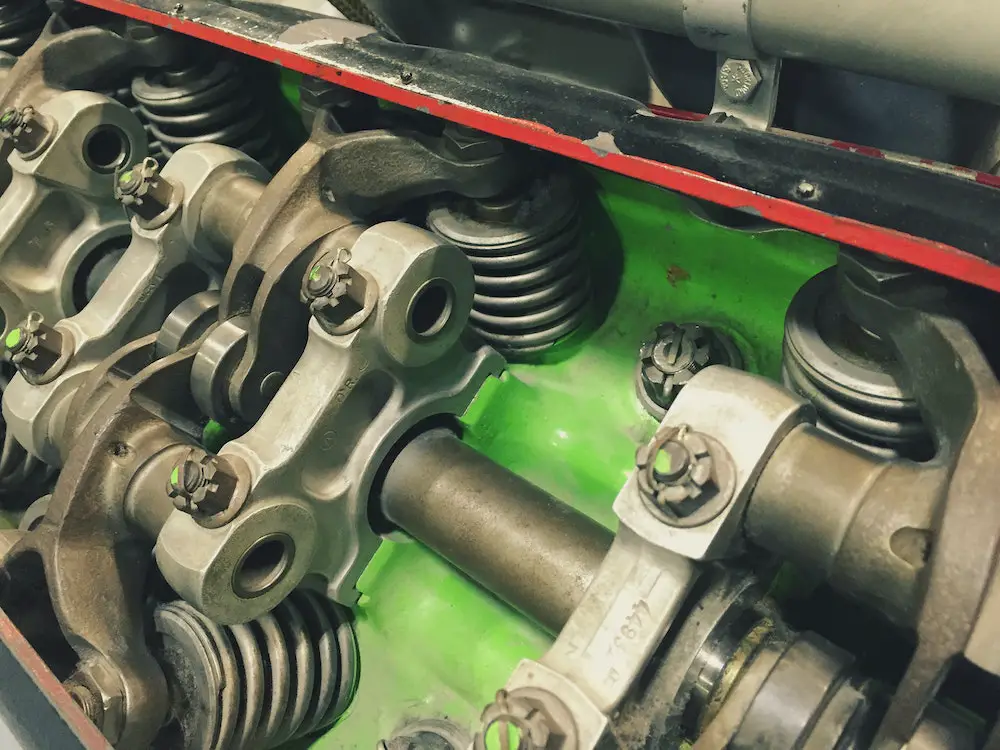

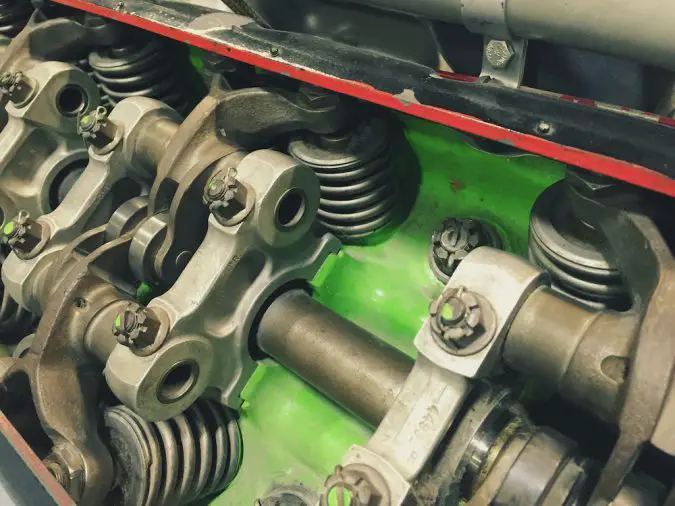

The camshaft in an internal combustion engine sits inside the cylinder head if you have an overhead cam engine. This can be two camshafts if your engine is a double overhead cam engine. Double this again, if it is a V-engine, with more than one bank of the cylinder. Then you have the W-engines, you get the idea.

The Over-Head Cam engines (OHC) require a longer connection between the camshaft and crankshaft. This is due to the position of the camshaft in the head, far from the crankshaft. Also, OHC engines also require more connections between them if there is more than one camshaft.

In pushrod engines, the camshaft is located next to the crankshaft, making it a simpler design. The camshaft need not have a long connection with the crankshaft. The head can be more compact as well. Yet, these engines are considered more primitive than the OHC engines. This is because the pushrods are not fast enough to attain higher revs with ease. But in their defense, these kinds of engines produce better low-end torque than most OHC engines.

With the camshaft done and dusted, let us look at what role the camshaft position sensor plays in this whole scene.

Why Do You Need A Camshaft Position Sensor?

The crankshaft and camshaft hold hands when an engine performs. Well, not literally. Maybe a bit literally, as they do have a physical connection between them. But the connection between them is crucial for effective performance.

The timing belt ensures the rhythm between the crankshaft and camshaft. This gives the camshaft a specific position with relation to the crankshaft at a given time. The camshaft position sensor reads this position and passes it on to the Powertrain Control Module (PCM). The PCM uses this info to fuel injector control and ignition system control. Thus, the PCM needs the input from the camshaft position sensor to plan for effective fuel supply and ignition.

The camshaft position sensor works in a similar fashion to the crankshaft position sensor. This is yet another sensor in this elaborate system. As its name suggests, the crankshaft position sensor reads the position of the crankshaft and sends it to the PCM.

The PCM uses this information, along with the camshaft position sensor data to calculate fuel and ignition variables. If there is a mismatch in the data from the camshaft position sensor and crankshaft position sensor, the engine knows that the timing is off, and throws warnings at the driver. What warnings? We will find out about them in the later sections.

How Does A Camshaft Position Sensor Work?

Camshaft position sensors come in different types. The MRE (Magnetic Resistance Element) type is more widely used so we will focus on the same for easy understanding. The MRE camshaft position sensor, as its name hints, uses magnetic fields and fluctuating resistance to detect the position of the camshaft.

In the case of an Overhead Cam Camshaft engine, the camshaft position sensor is positioned inside the cylinder head. The position right next to the camshaft enables it to create a magnetic field that the rotating camshaft lobes can interfere with. There is a detection tooth on the timing rotor on the camshaft.

As the camshaft rotates, the position of the timing tooth changes with respect to the camshaft position sensor. This movement of the tooth in and out of the magnetic field created by the sensor changes the MRE resistance value. This change in resistance is recorded by the sensor as fluctuating voltage.

Voltage data regarding the camshaft position is then passed on to the Powertrain Control Module, after converting it into a rectangular waveform. This gives the PCM a digital input to control the remaining parameters of the engine.

What Does The PCM Do With This Data?

The PCM uses this information to make many important decisions. The most important of which is to understand which stroke the cylinder is on. This gives it further information on how to adjust the fuelling and ignition. The PCM then instructs the fuel injector on the timing and quantity of fuel injection. The injector conforms to this command and injects the right amount of fuel at the right time.

Once the fuel is injected, the PCM uses the information from the camshaft position sensor to determine the optimum time for igniting the fuel. Once this is determined, the ignition circuit is given the go. The spark plugs light up, and there you have your explosion to power the engine.

With the important role to play in the operation of an engine, the health of the camshaft position sensor is pivotal. So how do you keep this sensor healthy? What happens if it goes wrong? Let us find out.

Camshaft Position Sensor Problems

The camshaft position sensor is an electronic component that can be affected by any parameters including fluctuations in voltage, short circuits, accidents, and a bunch of other issues. An issue with the camshaft position sensor ignored can end up damaging your engine so this is not something you should take lightly.

In this section, we will run through a list of possible symptoms that may hint towards a faulty camshaft position sensor. With these issues, we will throw a bit of light on what effect these might have on your vehicle.

1. Check Engine Light Comes On

This is not a surprise. In the event of a sensor failure, the engine will get the timing all wrong. Fuel injection and ignition timings can all get messed up. This can lead to an engine failure later. Hence, your car does the one thing it is supposed to do in these kinds of events, glow the engine warning light.

But a lit-up check engine light does not point directly towards a faulty camshaft position sensor. There are a variety of issues that can cause the light can come on. These range from an oxygen sensor gone bad to a damaged catalytic converter. You can read about a few over here.

If the check engine light comes on, no time should be wasted on waiting. Being negligent when there is a warning light on the dash can end up costing a lot more in repair than it would have if acted on it before. If it is a critical issue, it can end up catastrophically damaging your engine. This can hike your bill up to the thousands.

So, the moment you find an engine check light glowing, get your car to your trusted garage. Ask the mechanic to scan and inspect your vehicle to spot any critical defects. This can help you spot an engine failure long before it even happens. An engine rebuild can be hard on the wallet as well as the longevity of your car.

2. Ignition Issues

The camshaft position sensor, as we know, senses the timing on the camshaft. We have also learned that the Powertrain Control Module (PCM) uses this information to control fuel injection and its ignition. So, the most obvious effect of a faulty camshaft position sensor is the failure of these two processes.

In the event of a sensor failure, the PCM finds it hard to understand what the camshaft’s position is. The PCM may choose not to trigger ignition in this situation, leaving the engine unable to start.

If your car hesitates to start, it can be a camshaft position sensor failure. But it can mean other things as well.

3. Car Jerking

As we have seen, a failed camshaft position sensor can send wrong signals to the PCM, or not send any at all. This can cause the PCM to send the wrong signals to the fuel injection and ignition systems. When fuelling and ignition are incorrectly done, the behavior of the vehicle can be badly affected.

An instance of this happening is when your car starts jerking in the middle of a drive or when idle. This can mean that the fuel injection or ignition is not done properly, because of the erroneous signals sent by a camshaft position sensor gone wrong.

4. Sudden Acceleration

Just like the previous symptom, wrong fuel injection and ignition can end up messing up the power supply. This can mean that erratic acceleration behavior is a given when the camshaft position sensor gives up.

When it goes bad, the PCM may take wrong signals and make untimely decisions. One of these decisions can be to provide more throttle, randomly surging the car forward. This can happen mid-drive or the moment you slot your vehicle into drive or first gear if you are one of the stick shift aficionados.

5. Poor Acceleration

What goes opposite to more throttle? Less throttle. Yet another unpredictable throttle behavior when the camshaft position sensor goes wrong is poor acceleration. This happens when the fuel injectors are told by the powertrain control module to inject less fuel as it is unaware of the situation of the camshaft.

A reduction in fuel supply can reduce power output significantly and cause the vehicle to have poor acceleration. It can mean that you may have a hard time going past low speeds like 30 mph.

6. Engine Stalling

If the previous problem deals with low fuel supply, there can be instances when the fuel supply completely cuts out. The wrong signals the PCM receive may make it decide not to inject fuel into the engine at all. This can stall your engine while you are driving or completely shuts off.

If your car shuts off when you are at highway speeds, this can be a potential threat. Your car can also stall when you are pulling away from the lights, causing a lot of embarrassment.

7. Transmission Issues

Faulty camshaft position sensors can cause your transmission to lock itself in a single gear. It will refuse to shift up or down and remain in the gear. If you want to come out of it, you will have to shut off the engine and restart it.

This is in no way a permanent fix though. To get rid of this issue, the only way out is to replace the faulty sensor. To make matters worse, the vehicle may also go into “limp mode” leaving you unable to accelerate beyond a certain gear or shift beyond a certain gear. You would not want that when you are rushing to your office on a busy Monday morning. Here is your incentive for keeping the camshaft position sensor happy and healthy.

8. Lower Fuel Efficiency

A system that controls the fuel injection of an engine is easily the most responsible component for fuel efficiency So it may come to you as no surprise that wrong signals from the PCM can cause the efficiency of an engine to go for a toss. What makes the PCM churn out wrong decisions? There are many reasons and a bad camshaft position sensor is one among them.

This is mostly the opposite of what happens when less fuel is pumped into the engine, causing poor acceleration or engine stalling. Cylinders get more fuel injected in, dropping the fuel efficiency beyond favorable levels. This is in no way an ideal situation but there is a way to make it worse. This additional fuel may also cause bouts of acceleration, making the drive dangerous as well.

Cost Of A Camshaft Position Sensor Replacement

With all these potential repairs right at the horizon, you may want to jump in and replace the faulty sensor. That too, in a hurry. Worry not, this is not an issue that will break your bank.

A new camshaft position sensor will set you back by around $25-$100. The labor to replace that will add a healthy $70-$100 to the total amount. This may look a little beyond “easy on the pocket”. But considering the amount the repair costs of the aftereffects caused by not replacing the sensor, it is not that much.

As always, these costs depend on a lot of factors, the make and model of the car being a very important one. It will also vary according to your brand of sensor, location, and garage. But what if you want to bypass the high labor charges? Is it something that you can carry out in your own garage?

Camshaft Position Sensor Replacement – DIY

Yes, the camshaft position sensor replacement process is something that most people can do. It does not require years of experience in repairing cars. It is a 10-min task that anyone with the right tools can do.

Diagnosing a camshaft position sensor before you jump in and replace it will be a great idea though. The symptoms triggered by a bad sensor can be like a lot of other issues. Here is a video that can help you diagnose the camshaft position sensor

Step-By-Step Instructions For A Camshaft Position Sensor Replacement

- Disconnect the negative cable of the battery

- You need to find out the location of the sensor. Refer to the repair manual, or videos on YouTube to find out the exact location, as it varies from model to model. It is found mostly on the top, front, or rear of the engine with a couple or more wires attached to it.

- Unplug the sensor by pressing the release tab on the top and pulling back the wire connector. Make sure that you remember the orientation of the sensor as well as the wires before you pull them out. Take a few pictures to help you remember.

- Use a wrench to unscrew the bolt fastening the sensor to the engine. The size of the spanner needed depends on the make and model of your vehicle, but it mostly is an 8 mm or 10 mm bolt.

- Gently twist the sensor a bit and pull it off.

- Unbox your new sensor and apply a bit of engine oil to its O-ring.

- Install and bolt down the new sensor in the same orientation as before. The pictures you took early come in handy here, eh?

- Reconnect the wire connector to the sensor.

- Ride away and check if all the symptoms you saw before have vanished. Especially, the engine check light. If they are still there, you may have to diagnose it a bit more deeply to find the actual issue under the hood.

Here is a visual guide of the process of camshaft position sensor replacement

What Causes Camshaft Position Sensor Failure?

The camshaft position sensor is a key electronic component inside a car. Just like all electronic components, it is also susceptible to timely wear, as well as electric issues. Here are a few causes of camshaft position sensor failure and how you can deal with them.

1. Normal Wear

This is the most obvious cause of a camshaft position sensor failure. Every component in a vehicle is built for a time period. They all fail sooner or later. The time in which they fail depends on the manufacturer/supplier of the sensor.

But normal wear is not something that we can bypass. The sensor will fail at one point and we will have to make the investment of replacing it. Having a keen eye to spot the symptoms of a possible camshaft position sensor failure can help you identify this failure earlier. This can help you save a lot more money than you may otherwise spend on engine works if you ignore the warnings.

2. Accidents

If your car has been in a frontal accident, it is a good idea to inspect the camshaft position sensor during repairs. In fact, it is advised to replace the unit as it is relatively fragile and can be easily damaged. Replacing the sensor right away can help you save more costs down the road.

3. Electric Short Circuits

This can be triggered by many factors. Rodent attacks, flood damage, unauthorized electrical accessories, wrong battery connection et cetera. Modern vehicles have different measures to counter a catastrophic failure in these situations but there is a limit to what they can do.

If you know that there had been a short circuit and your vehicle is showing warnings, get the sensor checked. Replace it if necessary. Your wallet will thank you one day.

Camshaft Position Sensor: What You Need to Know – Facts

- A camshaft position sensor monitors the position and speed of the camshaft and feeds that data to the engine control module (ECM) to control fuel and ignition timing, increasing power and fuel economy while decreasing emissions.

- A bad camshaft position sensor may give warning signs such as a lit Check Engine light, poor drivability, transmission shifting problems, bad fuel economy, and eventually, engine failure.

- On modern auto-start/auto-stop engines, the camshaft position sensor determines which cylinder is in its power stroke relative to the crankshaft position to start the engine when you step on the accelerator.

- Ignoring the Check Engine light can lead to expensive engine or transmission repairs, and a failing camshaft position sensor can cause the engine to sputter, lack power, stall, or shut off.

- Inaccurate camshaft position sensor data can cause excess fuel to enter the combustion chamber, leading to engine knocking and serious damage.

- A failing camshaft position sensor can keep transmission shift solenoids from operating and gears from shifting, which can cause the engine to go into “limp-home-mode” to protect it from damage by restricting engine speed.

- As the camshaft position sensor weakens, the data signal it transmits to the ECM becomes weaker, causing the ECM to switch off fuel and spark delivery, eventually leading to engine failure.

- It’s best to take the vehicle to a professional when the Check Engine light illuminates, rather than attempting to diagnose the problem yourself using a DIY scan tool.

- A bad camshaft position sensor can give you a warning before it completely fails, so it’s important to pay attention to warning signs and address them promptly to avoid costly repairs and dangerous situations.

- The camshaft position sensor is just one of many sensors that help a car’s computer get the maximum performance out of the engine, replacing the days of carburetors and distributors.

What Have We Learned?

The camshaft position sensor is a pretty subtle yet key component of our engine that most people overlook. It may look tiny and cute but it contains the potential to completely wreak havoc on your engine if ignored completely.

So, get your sleeves up and check your camshaft position sensor, especially if you have an old car. Investing a little bit of money and elbow grease now can save you a lot more money, and sweat (and maybe some tears) later on.