A cylinder head repair is one of the nightmares any car owner can have during her/his car ownership. The complexity of the job and the fact that it disables the heart of your vehicle frightens many. But is this fear warranted? Let us dig deep into the details of cylinder head repair to figure out what it is, how it is done, and how much it will cost you.

The cylinder head is one of the most elemental structural parts of an engine. Made with high-strength metals, this is not a part that breaks often. But if it does, it is not a sweet job either. Here, in this story, we will discuss the following aspects to understand this topic better.

- What Is A Cylinder Head?

- Why Cylinder Head Repair?

- How Is Cylinder Head Repair Done?

- Cost Of Cylinder Head Repair

Without any further ado, let us see what each of these topics holds.

What Is A Cylinder Head

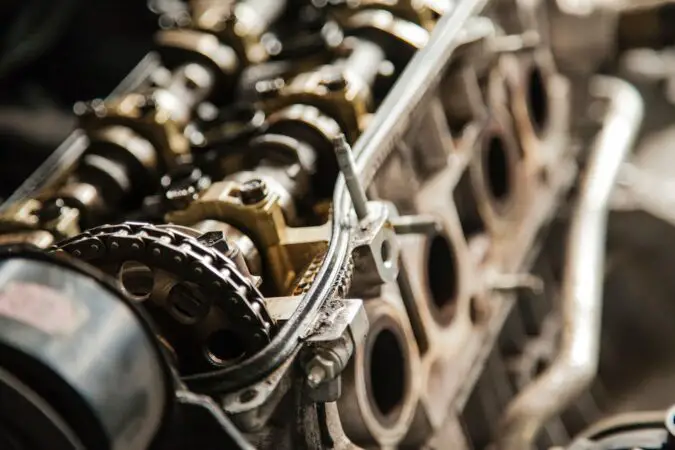

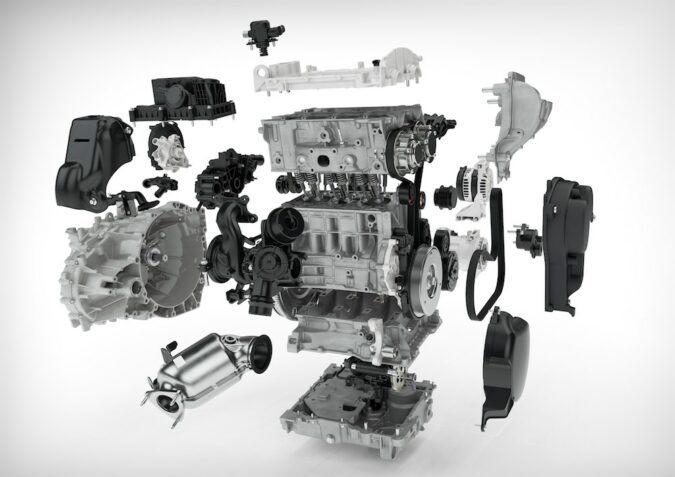

Anyone who has seen the basic picture of an engine can easily spot the cylinder head. As we said, this is one of the most important structural elements of an internal combustion engine. With the cam cover, cylinder block, crankcase, and oil pan, the cylinder head completes the basic outer structure of an engine.

Apart from this design role, it also houses the intake and exhaust valves, and the camshaft. Not just that, it also routes the air into these valves and then, into the combustion chamber. The exhaust gases leave the engine through the head itself.

With such a vital role in the engine’s design, a cylinder head repair is equally important. But as important or more important than the design of the cylinder head is its function. Let us look at both these aspects of this part to understand more about it, and the cylinder head repair process.

Cylinder Head Design

We head into this section with a clear idea of what a cylinder head is. But to understand the design and construction of this vital engine part, we should understand its function. The function of any mechanical part contributes heavily to its design. Let us look at how each of its functions adds up to create the cylinder head that we now know of.

1. Providing Strength

The first function of the cylinder head is to give structure and strength to the engine. It forms the key top part of an engine that contains high temperatures and pressures. Thus, the cylinder head is made to be extremely strong. The design of the cylinder head has something to do with this role but for the most part, the materials used in its construction contribute to its strength.

To add more strength to the engine, metals instantly become the no-nonsense choice for making the cylinder head. In the olden days, manufacturers used to cast both the cylinder head and the block together. Now, manufacturers cast them separately, with the head gasket providing a tight seal between them.

Cast iron used to be a choice for many manufacturers before. The high strength of the steel attracted them to it. Steel was also a good conductor of heat, improving its argument. But some of its disadvantages played against it, slowly fading it away from the scene.

Nowadays, cast iron heads have given way to aluminum alloy heads. The lower weight of the aluminum as well as its high thermal conductivity attracted more manufacturers to it. These alloys may vary in composition but they usually contain traces of Copper, Silicon, and Manganese to improve their favorable properties.

As it is playing such a vital role in the entire engine’s structure, the importance of cylinder head repair is equally high. It is not a maintenance aspect to overlook.

2. Housing Camshaft And Valves

When we talk about cylinder head repair, the camshafts and valves often spring into the picture. In some engines, these components rest inside or on top of the cylinder head. The cylinder head provides the room and support for the smooth functioning of these components.

Without proper functioning of the intake and exhaust valves, the engine will never breathe. The timing of these valves is also critical. A properly timed camshaft achieves this. The cylinder head may also provide room for this, depending on the type of the engine.

In old-school Pushrod engines, the camshaft sits below the engine block, closer to the crankshaft. The cylinder head in these engines only has to accommodate the valves and the rocker arms that actuate them. The design of these cylinder heads also considers the free movement of the pushrods that move these rocker arms.

In Over Head Cam (OHC) engines, the camshaft makes its way to the top of the cylinder head. To ensure proper valve timing, the cylinder head provides support for the camshaft and the gears fitted to it. This helps the camshaft be in sync with the rotation of the crankshaft that sits under the engine block.

In the case of Single Over Head Cam (SOHC) engines, there will only be one camshaft for all valves. But in the more modern Double Over Head Cam (DOHC) engines, there will be two camshafts. One of these will actuate the intake valves while the other acts on the exhaust valves.

But no matter which engine we talk about, the cylinder head plays a crucial role in accommodating these key elements. They let the engine breathe, and the cylinder head gives them room to function well. More reasons to take cylinder head repair seriously.

3. Forming Combustion Chamber

This may be one of the most important functions of a cylinder head. The combustion chamber of an engine is the area left in the cylinder when the piston is at the top dead center. In most engines, depressions in the cylinder head form the majority of this volume.

Thus, the design of this cavity in the cylinder head directly affects the thermal performance of the engine. Also, the immense temperature and pressure that form inside this chamber can lead to cylinder head repair. Hence, the cylinder head is carefully designed in order to accommodate the requirements of a combustion chamber.

Modern cars utilize different shapes of combustion chambers. Each of these exhibits its unique characteristics, upsides, and downsides. Let us detail a few of them here to understand them better.

a. Hemispherical

As the name says, the combustion chamber is a hemisphere that accommodates the valves, equidistant from one another on either side of the chamber, with the spark plug in the middle. This design allows having larger valves.

b. Bathtub Design

This design is in the form of an inverted bathtub. Both the intake and exhaust valves sit at the top, side by side. This is a simpler design with the spark plug placed on the side. Bathtub design helps in increasing the turbulence inside the chamber for better mixing of fuel.

c. Wedge Design

The name hints at a wedge-shaped chamber that tapers to one side. The plug is located on the broader side and the valves sit, inclined at the longer edge. This shape offers less volume. It is beneficial in reducing hydrocarbon emissions. It also reduces the pressure exerted on the chamber, reducing the chances for a cylinder head repair.

d. Pentroof Design

This design employs a slightly taller hemispherical shape with two valves each for intake and exhaust. Despite being taller, the other smaller dimensions reduce the surface area of this type compared to the hemispherical design. Heat loss reduces with the smaller surface area, providing better gas mileage (more so if you know how to get better gas mileage).

4. Sealing The Combustion Chamber

As we know, the cylinder head provides structure and strength to the engine. In addition to that, it completes the combustion chamber of an engine, adding more importance to cylinder head repair. But to form a sealed combustion chamber, there should not be any leakage.

To achieve this, cylinder heads are tightly connected to the cylinder block. Long, sturdy studs/blocks are utilized to create this tight bond. This is not an area that can tolerate failure so these bolts are quite thick and has deep threads that screw into the block.

But as the cylinder head and the cylinder block are made of metal, creating a tight, leak-free fit is not easy with just some bolts. No matter how tight they are, there will still be leakage. This is where the head gasket comes in. This creates a tight seal between the block and the head. The design of the cylinder head is made with the fitment of the head gasket in mind.

5. Providing Lines For Coolant

Just like every other part of the engine, the cylinder head needs cooling. The absence of cooling can end up cracking the head, and lead to cylinder head repair. To enable cooling of the head, it contains channels for the flow of coolant. This takes away the heat from it quickly, reducing the chances of a cylinder head repair.

The material used to construct the cylinder head also helps reduce cylinder head repair by improving cooling. Aluminum is a popular choice for making cylinder heads not only because of its lightness, but also its thermal conductivity. Aluminum conducts heat faster than cast iron, hence carrying the heat away from the head quickly. The heat transfers faster to the coolant in the case of an aluminum head.

With the function and design of the cylinder head all clear, let us focus on the subject at hand, cylinder head repair.

Cylinder Head Repair: Why Is It Needed?

Cylinder head repair is not a maintenance task that is done at regular intervals. Instead, it is one of the ultimate failures an engine can have. If you have a well-maintained vehicle, this may not appear at all. But if that is not the case, you may have to face it at one point.

Despite the fact that aluminum heads come with multiple advantages, it is not as strong as cast iron heads. This means that aluminum heads are prone to damage, and end up in need of a cylinder head repair. Cast iron heads can last longer but that does not mean that the aluminum blocks fail very frequently. Failure of the cylinder head is seen very rarely, no matter what type of head your engine has.

But what warrants a cylinder head repair? Being a non-moving part, the only possible damage that can demand a cylinder head repair is cracks forming on it. These cracks do not develop that easily, as cylinder heads are made of sturdy metal. Here is a list of all that can cause the cylinder head to crack.

Causes Of Cylinder Head Damage

As we spoke already, the cylinder head cracks only in extreme situations. There are multiple causes that can lead to the creation of these extreme situations but most of them end up with the cylinder head overheating.

Cylinder Head Repair Causes #1: Engine Overheating

Engine overheating is easily the most common cause of cylinder head cracks. It is no secret that internal combustion engines make a lot of heat. All internal components are built to take this ordeal. This includes the cylinder head which is designed with this heat in mind. But everything has a limit and there is an answer to “how much is too much?”

The engine can overheat from a list of causes. Running with low coolant, low engine oil levels, a radiator fan failure, and more. Engine overheating is also the end result of having air in your coolant, having a failed water pump, leaking coolant, or a failed thermostat.

No matter what the cause is, engine overheating is a nasty scenario. It can not only lead to a cylinder head repair but can also damage numerous other components inside the engine. Here we will discuss a few of them that can end up you going through an expensive cylinder head repair.

Cylinder Head Repair Causes #2: Air In Cooling System

The failure of the cooling system as we know can damage the head, and make way for the arrival of a cylinder head repair. But another issue connected to the cooling system that has the same effect is the formation of air bubbles in it. The air bubbles can end up creating hot spots in the system.

As the name clearly suggests, the hot spots have locally elevated temperatures. This will be higher than what the engine temperature sensor picks up at its location. Air cannot conduct heat as easily as a liquid does, hence the temperature can soar high, even without the detection of the sensor.

Another drawback of having air in your cooling system includes a drop in coolant pressure. The elevated temperature and lowered pressure can lead the coolant to boil.

With all these unfavorable situations combined, the temperatures can go soaring, damaging the head.

Cylinder Head Repair Causes #3: Water Pump Failure

Of course, the coolant takes heat away from the engine, saving it from a cylinder head repair. But what happens if the coolant is unable to travel through this system? No points for guessing.

The water pump is responsible for pushing the coolant through the system. A failure in its operation can mean that coolant will not pass through at the required speeds. The coolant may be cold in the radiator but this will not get pumped to the hot engine. The engine thus finds no effective way to transfer its heat away.

Heat rises in the engine and can go beyond tolerable levels. This can damage the head and can create a situation for cylinder head repair.

Cylinder Head Repair Causes #4: Leaking Coolant

Another coolant-related issue that can bring about a cylinder head repair is a coolant leak. This needs no explanation. A leak in the coolant depletes the amount of coolant needed to cool the engine.

The only way to avoid this is to regularly check for fluid leaks. Any fluid leaking from the vehicle is not a good sight but a coolant leak can be especially destructive. Check the reservoir as well as the radiator to ensure that there is no drop in the coolant level. But, make sure that you do not open the radiator cap of a hot engine. You do not want boiling hot coolant over your skin.

Special attention has to be given to the radiator cap as well. Though the part is quite inexpensive, its failure can end up creating issues that are far more complicated.

Cylinder Head Repair Causes #5: Thermostat Failure

The thermostat is a small part that plays a major role in the effective operation of an engine. Internal combustion engines work at their maximum efficiency in a small temperature window. Anything cooler or hotter than this can end up reducing its effectiveness.

This is where the thermostat’s operation becomes key. It acts as a valve that stops the coolant from flowing into the radiator until the engine warms up to its operating temperature. This is very helpful during the first starts on cold days.

Once the engine temperature reaches its working temperature, the thermostat opens. The coolant then flows into the system, keeping the engine temperatures in check. It closes again when the engine runs too cold.

If the thermostat gets stuck shut, the hot coolant from the engine stays in the engine. There will be no way for it to escape, and cool the engine. This can shoot up the engine temperature, cracking the head after a while. A cylinder head repair may be in order if you run your car for too long with a damaged thermostat.

Symptoms Of A Cracked Cylinder Head

Here is a list of things that you will have to watch out for.

1. Coolant Leak

Well, we meet again. The coolant leak that can cause the cylinder head to crack, can also be a symptom of the same issue. The cracks in the head can go through the coolant channels in them, causing the coolant to leak out.

So even if the cylinder head repair was not triggered by a coolant leak, a pool of coolant under your vehicle is a symptom to watch out for.

2. Oil Leak

Another fluid that flows through the cylinder head is the engine oil. So, just like the coolant, a crack in its channels can leak the oil out. Though a cracked head is not a common cause of oil leaks, it is worth giving a look.

3. Loss Of Power/Misfiring

If the cylinder head develops a crack, the compressed air inside the cylinder can escape through it. This reduces the efficiency of the engine and reduces performance. It can also cause a misfire.

4. Smoke From Engine

This is related to the coolant and oil leaks. These fluids can leak out of the engine of course but that is not the only route they can take. The cracks may take them inside the combustion chamber where they mix with the fuel. Result? A lot of white smoke from the exhaust.

How Is Cylinder Head Repair Done?

The cylinder head repair process depends on the depth and size of the cracks as well as the material used to make the cylinder head. As we can guess, if the cracks are too deep and large, you must replace the cylinder head. But in most cases, you can do cylinder head repair as it is basically just a solid piece of metal.

For aluminum heads, TIG welding is the preferred process for cylinder head repair. Welding not only binds the cracked head but also adds metal to the cracks, filling them in. This restores the original integrity and strength of the head. But in the case of cast iron heads, cylinder head repair is a bit more difficult.

For cast iron heads, the cylinder head repair is done using a process called Pinning as it is tough to weld cast iron. Skilled mechanics drill equidistant holes along the crack, which they then fill with pins that screw tightly into them. For additional strength, they may also use a sealer, depending on the pin type. Grinding down the pin heads helps them gel with the machined surface of the cylinder head.

To foster this even further, they drill even more holes after they finish grinding the first set of pins. Experienced mechanics drill these new holes between two of the older pins that now sit flush with the head, along the crack. The procedure is then repeated to form a strong bond.

How Much Does It Cost?

The cylinder head repair is an expensive repair as it involves a lot of labor. The procedure cost can start from $500, but with all costs included, you can expect to shell out up to $1,000 for this procedure. Depending on how many cracks your vehicle has, as well as the make and model of your vehicle, the cost can fly beyond $2,000 easily.

Cylinder Head Failure Facts:

- Cylinder head failure symptoms include a drop in coolant and oil levels, engine performance, and smoke from the exhaust.

- Overheating, caused by coolant loss, head gasket failure, or restricted coolant flow, is the most common reason for cylinder head failure, which can lead to terminal damage to the engine.

- Cylinder head repair and reconditioning costs can vary from $75 to hundreds of dollars depending on the value of the cylinder head and the extent of the damage.

- K-Seal can repair most cylinder head cracks or leaks, offering a cost-effective solution.

- A cylinder head sits on top of the engine block and creates the combustion chamber while connecting to the intake and exhaust manifolds to feed air and fuel to the cylinders.

- The intake and exhaust valves must open and close at the right times to ensure the engine runs smoothly.

- Cylinder heads can warp due to extreme temperature changes and pressure, which can lead to expensive problems later on.

- Cylinder heads made of aluminum are more prone to warping.

- Other parts of the engine can be affected if the cylinder head fails, and it is essential to deal with any problems promptly to prevent further damage.

- It is recommended to seek specialized mechanic services to realign a warped cylinder head or opt for replacement if required.