In stark contrast to older cars, modern automobiles have a wide array of sensors and other electronic gadgets that actively analyze, gauge, and help to optimize key components. For example, how to run the engine as effectively as possible, by understanding the right mixture of fuel and air for ignition to proceed. Thus, why we’re worried about issues such as how much does a mass air flow sensor cost.

As you might’ve guessed, internal combustion engines require two vital components to function; fuel and air. To ensure an optimal balance of performance, fuel economy, and with minimal impact as far as emissions are concerned, your engine has to carefully use as much fuel as it really needs to. For X amount of fresh air rushing into the engine, a corresponding Y amount of fuel is required to burn it.

But how can you measure just how much air is passing into the combustion chamber? Well, we could thank the mass air flow sensor for that, but measuring the air flow rate in real-time. Before, passing that data on to the ECU, which can then sufficiently measure just how much fuel it has to pump into the engine, respectively. Given its importance, how much does a mass air flow sensor cost, then?

What Is A Mass Air Flow Sensor?

Before we look at mass air flow sensor cost, it’s important to understand more about what this does within your car. So, what is a ‘mass air flow sensor’, and what does it do? As we mentioned, its job is to gauge the rate of air flow rushing past the intakes, and into the combustion chamber. For a more accurate picture, it works hand-in-hand with the oxygen sensor, as well as MAP and BARO sensors.

Altogether, these sensors can best inform the engine’s central command module, the ECU, about the air. Specifically, the volume of air, its speed, not to mention the air pressure, density, or atmosphere. In doing so, the ECU will be able to understand the amount of fuel it needs to pump into the engine. Consequently, making sure that each combustion cycle is as well optimized as it could’ve been.

Remember that engines work on a set air-to-fuel ratio. For the most ideal combustion (as is the case in most cars), ECUs follow the stoichiometric ratio of 14.7:1. In other words, 1 part (gram) of fuel for every 14.7 parts (gram) of air. As a very basic example, let’s say the mass air flow sensor (also known as the MAF sensor) sees that there is 29.4 grams (2 x 14.7) worth of air surging into the engine.

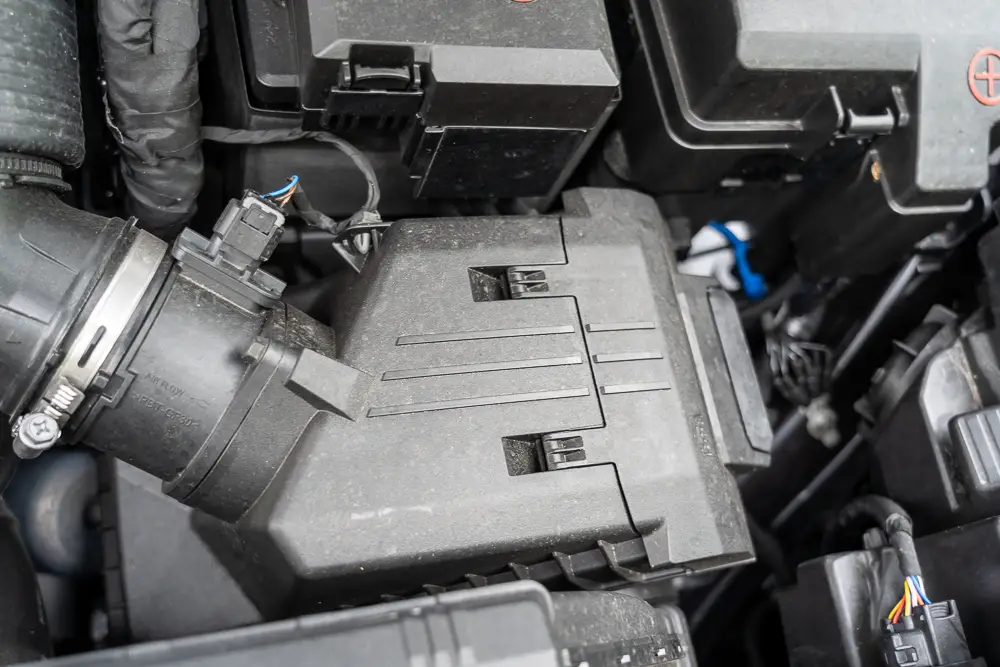

As the ECU reads this, it can then pump in 2 grams worth of fuel to mix in with that air to match that stoichiometric ratio. Given that it needs to analyze the flow of air, most vehicles have the MAF sensor buried inside the intake manifold, just behind the air filters. This is its best position, which places it on the pathway before the air gets into the engine. There are two types of mass air flow sensors.

How Do These MAF Sensors Work?

Those two distinct types are the ‘vane’ and ‘hot wire’ mass air flow sensors. While they have similar functions in analyzing metered air, they do work differently:

- Vane-Type Mass Air Flow Sensor – It consists of a spring that holds in place a vane. The latter is exposed to the air flow and is connected to a potentiometer. As air rushes past, it pushes the vane to rotate against the spring. As a result, the potentiometer slides along a track, as the other end is thus connected to a power supply unit. The corresponding slider movement will induce a voltage signal.

- Hot Wire-Type Mass Air Flow Sensor – This is commonly found on most modern cars. It uses a heated electrical wire that is exposed to the air flow. The wire is often made out of platinum, or other similar metals. As air flows past it, the heated tip of the wire will get cooler. Hence, needing more current to heat it up, and maintain a constant temperature. That electrical current becomes a signal to the ECU.

As you can see, neither sensor measures air flow rate directly. Rather, opting for more consistent and measurable inputs that can be extrapolated, and inform the ECU. Both of them also feature a similar pulse-width modulation of between 0.0 to 5.0 volts. This voltage output will be proportional to what air flow rate you’re getting and will be passed on to the ECU to be measured and analyzed properly.

Are There Any Other Types To Speak Of?

Technically, there are also three other types of MAF sensors in use. Albeit, they’re not as prominent as either a vane-type or hot wire sensor:

- Cold Wire-Type MAF Sensor – You’ll normally find these on General Motors’ LS series of engines. They work just like ‘hot wire’ MAF sensors. However, ‘cold wire’ sensors feature an additional resistor that measures ambient air. This ‘cold’ resistor compliments data collected by the hot wire, and measure air flow more accurately. Nevertheless, cold wire sensors require more maintenance to work right.

- Kármán Vortex MAF Sensor – This type of sensor uses a perpendicular bow that disrupts the air flow. In doing so, air oscillates around the bow, creating Kármán vortices. It can then use a light beam to measure the pulse and frequency of this oscillation, corresponding to air velocity. You’ll usually find this type of sensor in Mitsubishi, Toyota, Lexus, and BMW models, especially those with turbos.

- Membrane MAF Sensor – In this case, you’ll find a thin electronic membrane placed within the flow of air. Covering the top and bottom surface of the membrane, there’s a thinner temperature sensor film that measures constant temperature. Therefore, it follows a similar principle to hot wire sensors, as the current is used to gauge air flow. So far, membrane-type sensors are still experimental in nature.

What Causes Your Mass Air Flow Sensor To Fail?

It’s fair to say that mass air flow sensors go through a lot of use and abuse. On average, and within a MAF sensor’s lifespan, every liter of fuel used equates to around 9,000 liters of air that flows past the MAF sensor. Given that vast volume of air, mass air flow sensors are known to fail. Though they can last for up to 10 years, MAF sensors can easily get clogged up after just 20,000 to 25,000 miles.

Here are some of the most common causes why you have to worry about a mass air flow sensor cost:

- Contamination by dust, dirt, water ingress, and other impurities could clog it up.

- Constantly driving through dusty environments, exposing the sensor to even more clogging.

- Bad wiring or compromised contact points with the electrical connectors.

- Measuring elements (vane, heated ‘hot wire’, etc.) that have been damaged.

- Measuring elements have drifted from their original tolerances and specifications.

- Wear and tear are caused by constant vibrations and impact inside the engine.

- Engine oil contamination, usually from internal oil leaks that can foul up the readings.

- Damaged caused by physical contact or front-facing accidents.

It’s worth noting that mass air flow sensor failure is (ever so slightly) more common in smaller cars. A compact form factor forces MAF sensors to be placed within the tight confines of smaller engines. It’s thus in line with an increased risk of being clogged up by debris, and is vulnerable to oil vapor flows from a positive crankcase ventilation (PCV) system. But either way, MAF sensors can’t last forever.

It’s quite easy to tell when you eventually need to worry about a mass air flow sensor cost. Among its symptoms when the MAF sensor fails (or is on the verge of failing) include:

What Are The Symptoms From A Bad Mass Air Flow Sensor?

- Rough Idle – Without the ECU knowing how much fuel the engine needs, your engine will start to run pretty roughly. Vibrations and shakiness are common, as you’ll see the RPMs fluctuate rapidly.

- Stalling – Once again, the ECU has no clue about what amount of fuel is required. With likely too little of it in the combustion chamber, there’s a great risk of your car stalling out while driving or even during idling.

- Difficulty Starting – Without a sufficient mixture of either air or fuel, you may find it challenging for the engine to start. Otherwise, you might have to crank it a bit harder next time.

- Hesitation – With what’s most likely an incorrect amount of fuel, your engine won’t be optimized for performance. As such, there’ll be a momentary hesitation and shuddering while accelerating.

- Misfire – Misfiring is an instance where one or more cylinders isn’t combusting (or firing) properly. If the air-and-fuel mixture is out of whack caused by a bad MAF sensor, misfires may occur.

- Rich Or Lean – As the MAF sensors are out of commission, it’s not feasible to maintain a good air-to-fuel ratio. As such, your engine might run rich (too much fuel, not enough air) or lean (too much air, not enough fuel).

- Fuel Economy – Of course, faulty MAF sensors might prompt the ECU to pump far more fuel than the engine really needs. As such, you’ll begin to see an increase in fuel consumption, with lower MPGs.

- Check Engine Light – Should your ECU detect that the MAF sensor isn’t working right, it might throw up a check engine light. With that, it’s accompanied by an error code.

- Black Smoke – If your engine is running rich, it means that there’s unburnt fuel exiting through your tailpipes. When that happens, you’ll notice thick plumes of black or grey smoke.

How Can You Diagnose A Bad Mass Air Flow Sensor?

If your mass air flow sensor is on its way out, it’s relatively safe to keep driving for a little bit. Though you’ll have to live with the aforementioned symptoms. In short, bad performance, rough idling, high fuel consumption, and so on. As a whole, a bad MAF sensor wouldn’t scrap your engine right away, but only make your car’s driveability that bit more compromised and discomforting.

This should give you ample time to head over to a mechanic and get it checked out. Although, we’d recommend against waiting, and urge prompt action to be taken. A poor sensor will worsen how the engine will continue running. In addition, those symptoms, if left untreated for a long time, would rapidly accelerate wear and tear in the engine. This leads to pricier repairs down the line.

Should you notice the engine not functioning as smoothly as it used to, diagnosing the MAF sensor is the right step forward in troubleshooting it. To diagnose it, you can proceed with the following steps to take before considering how much does a mass air flow sensor cost:

Step 1: Check For Error Codes With An OBD2 Scanner

The easiest way to tell what’s wrong with your car is to plug in an OBD diagnostics tool. Your ECU is surprisingly efficient at spotting even the tiniest and subtlest of issues. This is quite helpful in the case of a bad MAF sensor, as the latter is among the most tedious components to diagnose.

Just a single error code could save countless hours worth of diagnosis, and pinpoints the exact cause of an underlying issue. Besides expediting the process, this may also prevent you from misdiagnosing any faults with your car. For a bad MAF sensor, look for any P01XX error codes.

In particular, those error codes between P0100 to P0199, relate to air flow-related sensors like the MAF, as well as MAP, BARO, and other similar sensors. The most common ones that relate to a bad MAF sensor include:

- P0100 – Mass Or Volume Air flow Circuit Malfunction

- P0101 – Mass Or Volume Air flow Circuit Range/Performance Problem

- P0102 – Mass Or Volume Air Flow Circuit Low Input

- P0103 – Mass Or Volume Air flow Circuit High Input

- P0104 – Mass Or Volume Air flow Circuit Intermittent

Note, fancier OBD scanners-slash-readers also enable you to visually see the MAF sensor readings in real-time. They’re usually measured by RPM. The higher your RPMs (engine speed), the more air that has to pass through the MAF sensors.

While you’re idling, the MAF sensor should be reading 0mg. It then steadily and gradually rises as the RPM builds up. Remember, this air flow value has to remain stable. For example, it might rise to 3mg at 1,000RPM, 6mg at 2,000RPM, 9mg at 3,000RPM, and so on.

Step 2: Make A Visual Inspection Of The MAF Sensor

While you’re around the engine, you could make a visual inspection of the MAF sensor. Take a peek at the wiring, in particular. Is there any corrosion, or perhaps visible signs of damage on the wires? Such as, fraying, burn marks, short circuits, and so forth.

Besides that, you should also look at the sensor itself. Do you notice any oily residue on it, or maybe debris like dirt getting clogged up near the measuring elements? Moreover, and given how sensitive the measuring elements are, see if there’s any damage or drifting there, too.

Once you’ve figured out that your MAF sensor is actually the one to blame, you can bench test it with a multimeter. This should provide you with an understanding as to whether the voltage output from the MAF sensor is in line with how it should perform under regular circumstances.

Should those voltage readings be out of spec, or notice how it fluctuates constantly, then you’ll know that the MAF sensor is faulty. You can start by turning the engine off, setting the transmission in ‘Park’, and engaging the handbrake. Once that’s done, you can proceed by:

Step 3: Testing The Mass Air Flow Sensor With A Multimeter

- Now, locate the MAF sensor in your car. In most cars, it should be located between the filter housing and the intake manifolds. For others, you might find it mounted just in front of the throttle bodies.

- You should refer to a service manual for the specific make and model of your car to know what range of voltage the MAF sensor should be operating at.

- Connect the multimeter’s red lead to the MAF sensor, and the black lead to the ground circuit.

- Now, you can fire up the engine, and keep it idling.

- While on idle, the MAF sensor should be reading somewhere between 0.5 to 0.7 volts on most cars. Again, this will vary depending on the make, model, and specifications of your vehicle.

- You could also gently tap the MAF sensor with the handle of a screwdriver. But, being careful to not physically hit the exposed measuring elements.

- With a quick tap of the sensor on idle, the readings should remain constant. Otherwise, any flux in the voltage readings is indicative of a fault with the wiring.

- Additionally, you can diagnose it further by revving the engine. Say, to around 2,500 to 3,000RPM. At this higher engine speed, the MAF sensor will be intaking more air.

- Now, take a look at the readings. It should read far higher than idle, approximately 2.0 to 2.5 volts (dependent on the vehicle).

- If the voltage doesn’t increase at all, then the entire sensor has failed.

- Since you already have a multimeter on hand, try contacting it against the measuring element with the ignition off, and the MAF sensor unplugged.

- Gently place the leads against the hot wire element. If it reads infinite resistance (showing up as ‘OL’ in ohms), then the hot wire itself is broken.

How Much Does A Mass Air Flow Replacement Cost?

If your diagnosis informs you that the MAF sensor has failed, then it’ll require a replacement. A rough average for a total mass air flow cost during a replacement is around $300. It could vary significantly depending on what vehicle you drive. In some instances, you could get away paying less than $100 to replace the mass air flow sensor, accounting for labor and parts. Or, it can rise to $500 or more.

You can find a fully functioning mass air flow sensor for as little as $30. Although, high-quality OEM-spec parts could cost you closer to $300. Meanwhile, labor charges are likely to be cheap, around a range of $50 to $80. This is owing to how accessible the MAF sensor is, requiring only plastic clips or simple mounts to be undone. Therefore, it shouldn’t take that much time to replace, either.

If you want to save on labor costs, it’s quite easy to manage a DIY mass air flow sensor replacement that takes mere minutes to perform:

- Always disconnect the battery before working on any electrical components, like the MAF sensor.

- Unplug the wires connecting to the MAF sensor by squeezing the plastic tabs holding it in place. Pull gently on the connectors to disconnect it, while being careful to not damage the wires.

- Now, you can disconnect the MAF sensor. You’ll need a screwdriver to loosen any screws, clamps, or mounts that keep the MAF sensor locked in place.

- Pull the old MAF sensor out, slot the replacement unit in, and repeat the steps in reverse. Just make sure you don’t physically touch or put a strain on the measuring elements.

- Double-check that the connectors are firmly secured, and give your car a short test drive to confirm that it all works properly.

Final Thoughts, And Cleaning A Mass Air Flow Sensor

Aha, but there’s a final trick to save on a mass air flow cost for replacement. For the most part, your MAF sensor’s malfunction isn’t attributed to complete failure. Rather, it’s plausible that there’s a lot of dirt contamination and clogging, to a point where its readings are inaccurate. So, and before you shell out for a mass air flow replacement, consider cleaning it first to see if that solves your issues.

Some recommend a good cleaning after every oil change. Or, at least once a year. You can start by:

- Disconnecting and removing the MAF sensor from its mounting.

- Place it on a towel, and grab a special MAF sensor cleaning solution.

- Give the MAF sensor a few squirts of this cleaner. Alternatively, you can use rubbing alcohol, instead.

- While you’re cleaning it, focus on the MAF sensor’s housing and connectors.

- Just make sure this cleaning solution doesn’t touch the measuring elements (hot wire, vane, etc.). You can carefully tape it up to prevent it from getting sprayed, just in case.

- Finally, let the MAF sensor dry out, and ensure that it’s properly dried. This should take around 20 minutes, or upwards of an hour if you’re using alcohol.

In all, that rounds up our guide on how much does a mass air flow sensor cost. While it’s a key piece of your engine’s operation, it’s quite easy for this component to fail or get clogged up with debris. If it does, however, at least it’s fairly straightforward to give it a good cleaning. Or, and if you really need to, an MAF sensor isn’t that expensive to replace. Just be wary to get it done in time.